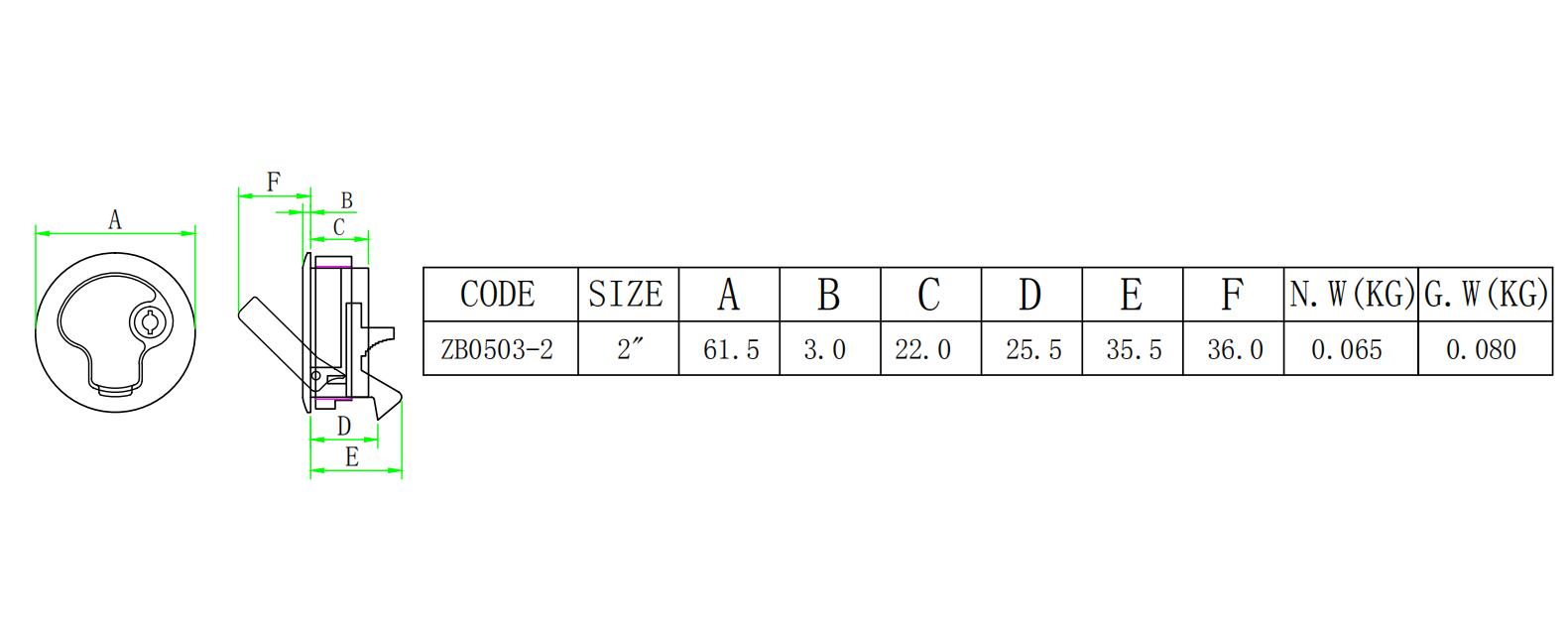

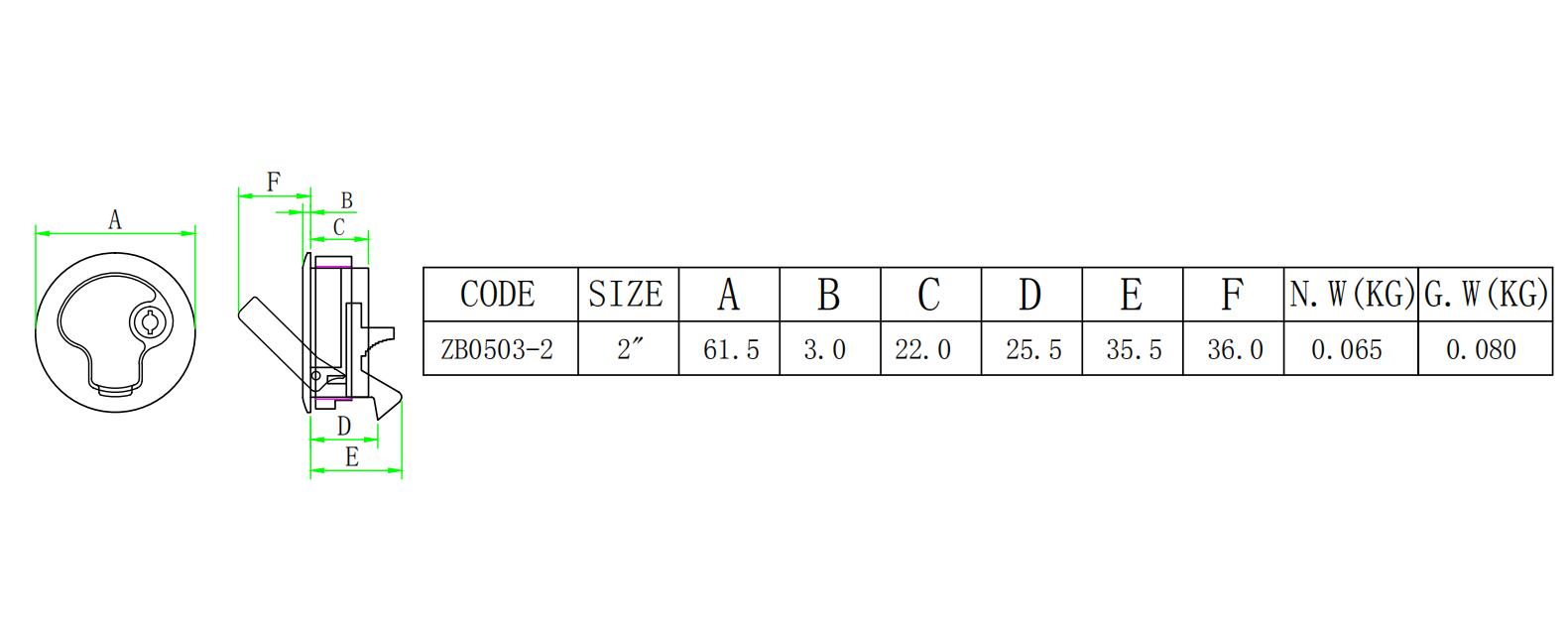

plastic marine latch with boat hardware

It is made of high-quality ABS engineering plastic and precisely manufactured. Corrosion-resistant and rust-free. Sturdy and durable.

Product Advantage

1.It has strong resistance to seawater corrosion and can adapt to marine environments.

2. Excellent resistance to pitting and crevice corrosion.

3. Good tolerance to various acidic and alkaline chemicals.

4. High strength, capable of withstanding considerable tension.

5. Excellent toughness, unlikely to break easily.

Product Name

| Plastic Marine Latch |

| Application | Boat Hardware Fitting |

Packing

| bubble bag + carton |

| Material | plastic |

| Lead time | 2-15 days. |

FAQ

Why does stainless steel have magnetism?

a。Often, people use magnets to test the quality of stainless steel. If a magnet doesn't attract and has no magnetism, it is genuine and of good value.

b.On the contrary, it is regarded as a counterfeit. In fact, this is an extremely one-sided and unrealistic method of wrong identification.

c.Austenitic stainless steel is non-magnetic or weakly magnetic. Martensitic or ferritic stainless steel is magnetic. However, when austenitic stainless steel undergoes cold working, the microstructure of the processed area will also transform into martensite.

d.The greater the degree of processing deformation, the more martensitic transformation occurs and the greater the magnetic property. The material of the product will not change. More professional methods should be adopted to test the material of stainless steel. (Spectral detection, stainless steel identification liquid detection).

Packing and Delivery

Exsibition