stainless steel slam latch

Preferred stainless steel 316 material,Good material and excellent polishing quality make it has good performance on anti-rust and corrosion resistance .

Product Advantage

1. Strong antioxidant properties, with a surface that is not prone to rusting and maintains a beautiful appearance.

2. The material is stable and shows little change in performance under different temperatures.

3. Excellent welding performance, easy to install and fix, with a secure and reliable connection.

4. The processing performance is excellent, and it can be manufactured into various complex shapes that fit the hull.

5. Non-magnetic, it will not interfere with the operation of the precise equipment on the ship.

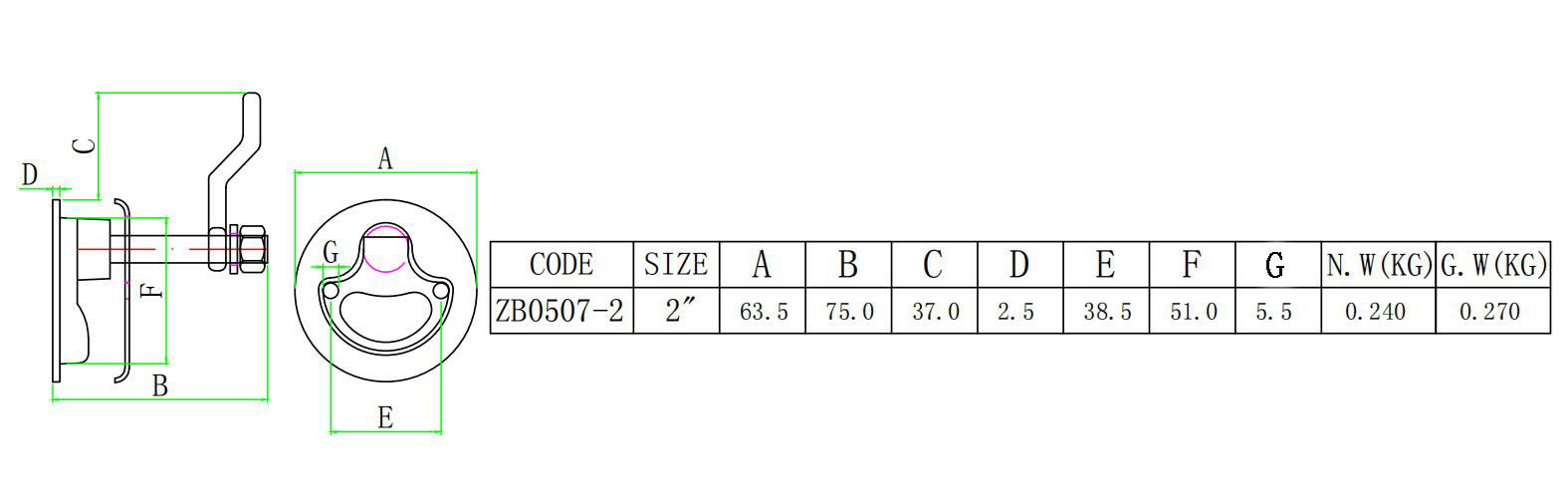

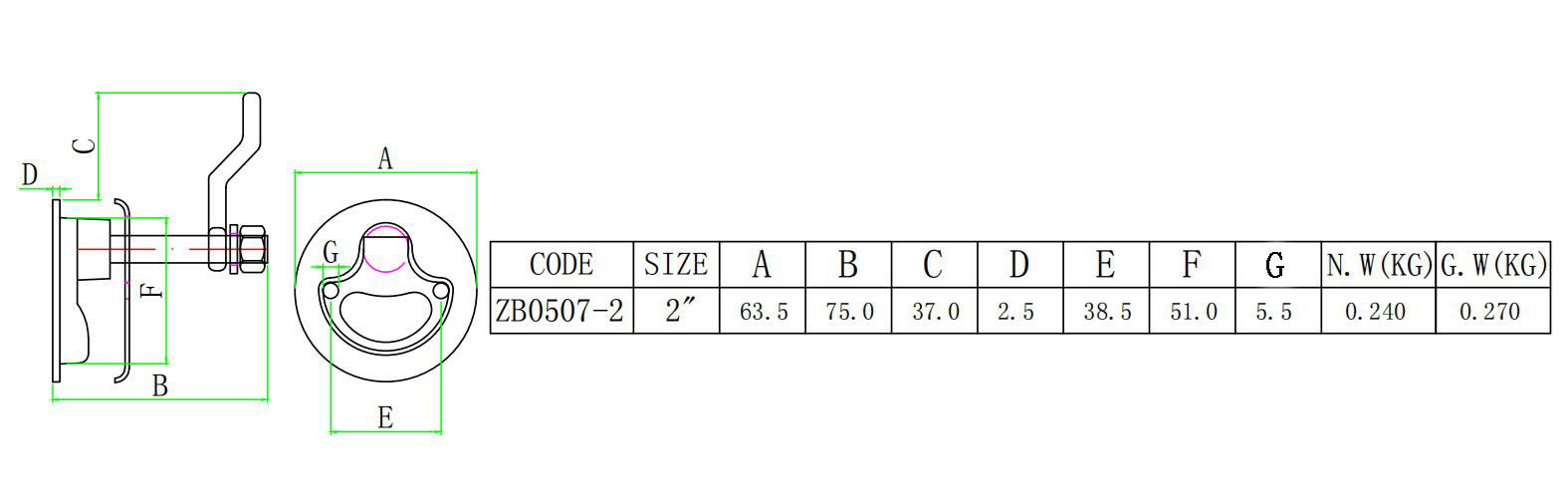

Technical Parameters

Product Uses

The slam latch is mirror polished by hand , which has shining look and smooth surface

This flush pull slam latch is perfect as handle for cabinet , drawer , ect.

This marine latch is made of SS 316 material , good performance on corrosion resistance It is precisely cast, corrosion-resistant and not prone to rust. Sturdy and durable.

The craftsmanship is rigorous. The surface is treated with high-precision polishing. Higher precision, brightness and polishing degree. Not only does it effectively prevent corrosion, but it also appears high-end and elegant.

Product Name

| Marine Latch |

| Application | Boat Hardware Fitting |

Packing

| bubble bag + carton |

| Material | SS316 |

| Lead time | 2-15 days. |

FAQ

1.Question: Which stainless steel grades are food-safe?

Answer:Common safe grades: 304 (everyday use), 316 (high corrosion resistance), and 430 (budget-friendly).

2.Question: What’s the difference between 304 and 430 stainless steel?

Answer:304 has nickel (non-magnetic, more corrosion-resistant); 430 has no nickel (magnetic, lower cost).

3. Question: How to clean stainless steel without scratching it?

Answer:Use a soft cloth + mild dish soap; avoid steel wool or abrasive sponges.

Packing and Delivery

Exsibition