508 marine latch stainless steel 316

Stainless steel 316 material is preferred. It is precisely cast, corrosion-resistant and not prone to rust. Sturdy and durable.The surface is polished . Good material and excellent polishing quality make it has good performance on anti-rust and corrosion resistance .

Product Advantage

1.The craftsmanship is rigorous. The surface is treated with high-precision polishing. Higher precision, brightness and polishing degree. Not only does it effectively prevent corrosion, but it also appears high-end and elegant.

2.The embedded pull ring design makes it more convenient to use.

3.It is independently packaged in bubble wrap to effectively prevent scratches and bumps during transportation.

Product Name

| Marine Latch |

| Application | Boat Hardware Fitting |

Packing

| bubble bag + carton |

| Material | SS316 |

| Lead time | 2-15 days. |

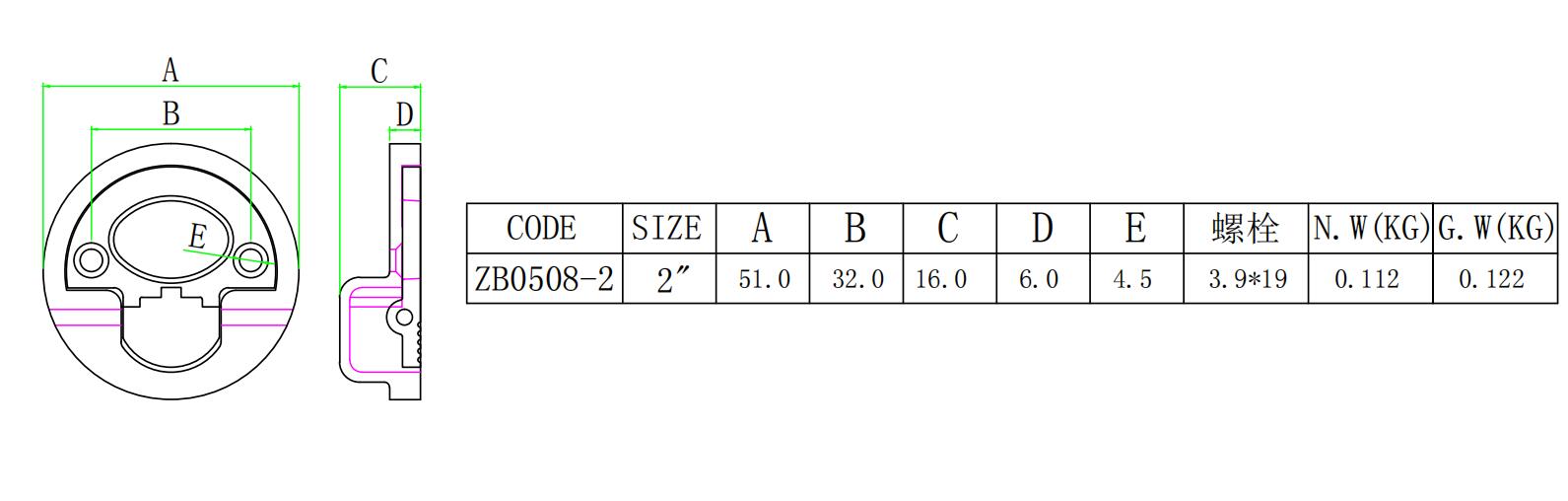

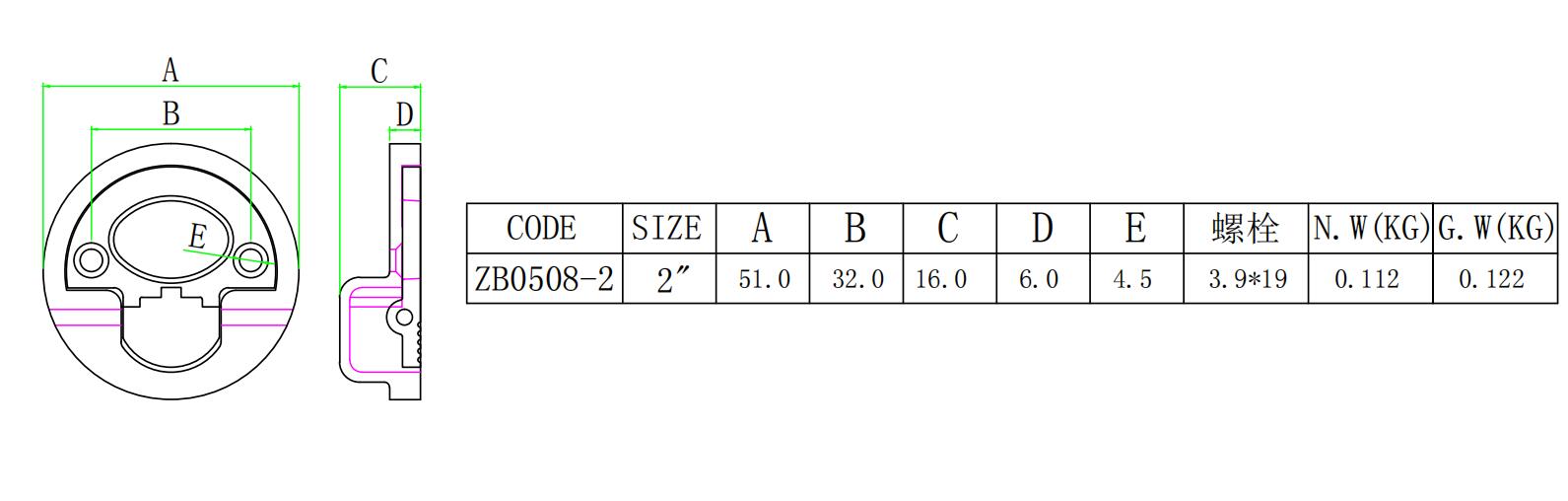

Technical Parameters

FAQ

Why does stainless steel rust?

a. When dust containing other metal elements or particles of dissimilar metals accumulate on the surface of stainless steel, in a humid environment, the condensate water between the adherent and the stainless steel forms a micro-battery, triggering an electrochemical reaction and damaging the protective film. This is known as electrochemical corrosion.

b. When organic substances such as vegetable juice, noodle soup, and phlegm adhere to the surface of stainless steel, they form organic acids in the presence of water and oxygen. Over a long period of time, these organic acids will corrode the metal surface.

c. The stainless steel surface adheres to substances containing acids, alkalis and salts (such as splashed alkali water and lime water during wall decoration), causing local corrosion.

d. In polluted air (such as that containing large amounts of sulfides, carbon oxides, and nitrogen oxides), upon encountering condensation water, liquid spots of sulfuric acid, nitric acid, and acetic acid are formed, causing chemical corrosion.

Packing and Delivery

Exsibition