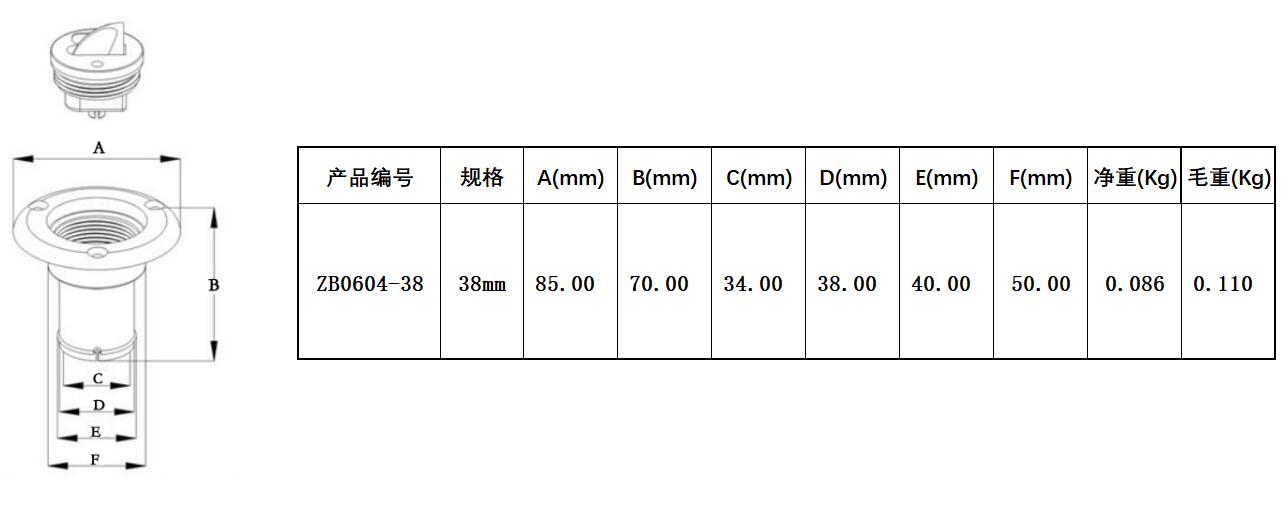

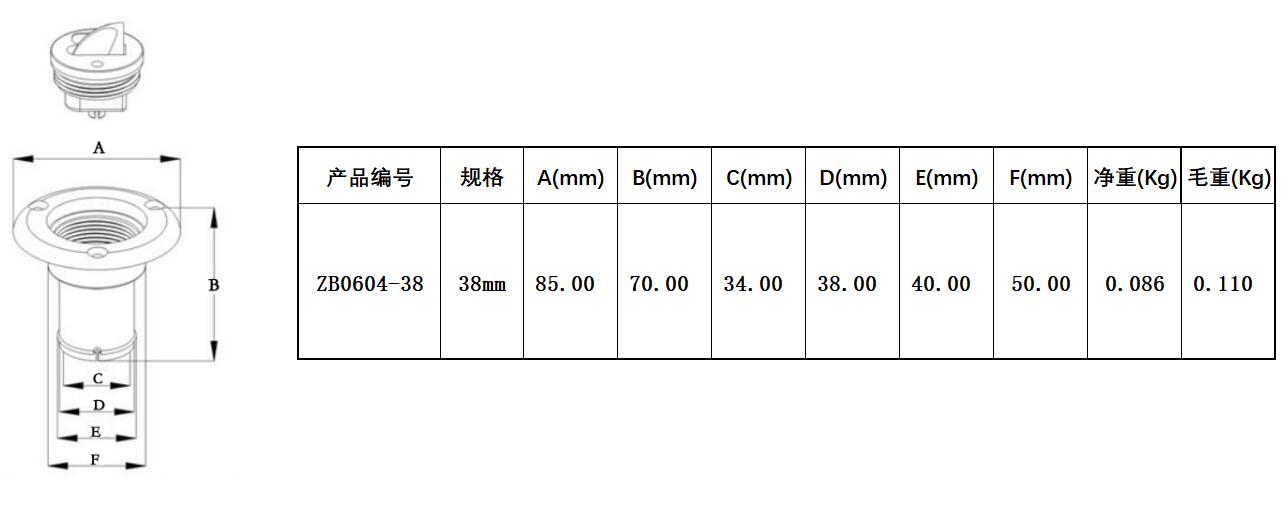

Marine Hardware Deck Filler Socket of Fuel Plastic 38mm

Product Overview

1. Marine Plastic Fuel Filler Neck

Made of durable marine-grade plastic, it resists fuel corrosion and UV damage, ideal for small boats and yachts.

2. Universal Marine Fuel Fill Port

Lightweight plastic construction with a tight-sealing cap, fits most fuel tank types for hassle-free installation.

3. Leak-Proof Marine Plastic Fuel Filler

Features a double-seal design to prevent fuel leakage, suitable for both gasoline and diesel marine applications.

Opening Diameter:

38mm

Product Advantage

1. Marine Plastic Fuel Filler Neck

Marine-grade plastic construction delivers excellent resistance to fuel corrosion and UV rays, ensuring long-lasting performance at sea.

2. Universal Marine Fuel Fill Port

Lightweight yet sturdy design enables quick, hassle-free installation that fits most standard marine fuel tanks.

3. Leak-Proof Marine Plastic Fuel Filler

Double-seal cap design effectively prevents fuel leakage, enhancing safety for both gasolin.e and diesel vessel applications.

Specifications & Dimensions

Application Scenarios

1. Ideal for small recreational boats and fishing vessels for daily fuel refueling.

2. Perfect for yachts and luxury cruisers, matching the deck’s aesthetic while ensuring fuel tightness.

3. Suitable for work boats and commercial ships, adapting to frequent and high-volume fuel filling operations.

FAQ:

1. Why does stainless steel turn blue/purple?

High heat (e.g., overheating a pan) causes a chemical reaction in the oxide layer, changing its color.

2.How to remove water spots from stainless steel?

Wipe with a damp cloth + white vinegar, then dry immediately with a clean towel.

3.Can I put stainless steel in the microwave?

Most are microwave-safe, but avoid those with metal handles or decorative accents.

Packing&Delivery

Exhibition