Marine Heater Thru Hull Exhaust Skin Fitting 316 Stainless Steel Boat Latch

Product Overview

1. Marine Stainless Steel Steam Exhaust Pipe

Crafted from 316 stainless steel, this pipe resists saltwater corrosion and high temperatures, ideal for marine engine steam discharge systems.

2. High-Pressure Marine Steam Exhaust Pipe

Made of heavy-duty stainless steel, it handles high-pressure steam output, with a leak-proof design suitable for ship boilers and power units.

3. Universal Marine Steam Vent Pipe

304/316 stainless steel construction for versatile installation, featuring smooth inner walls to ensure unobstructed steam flow on vessels.

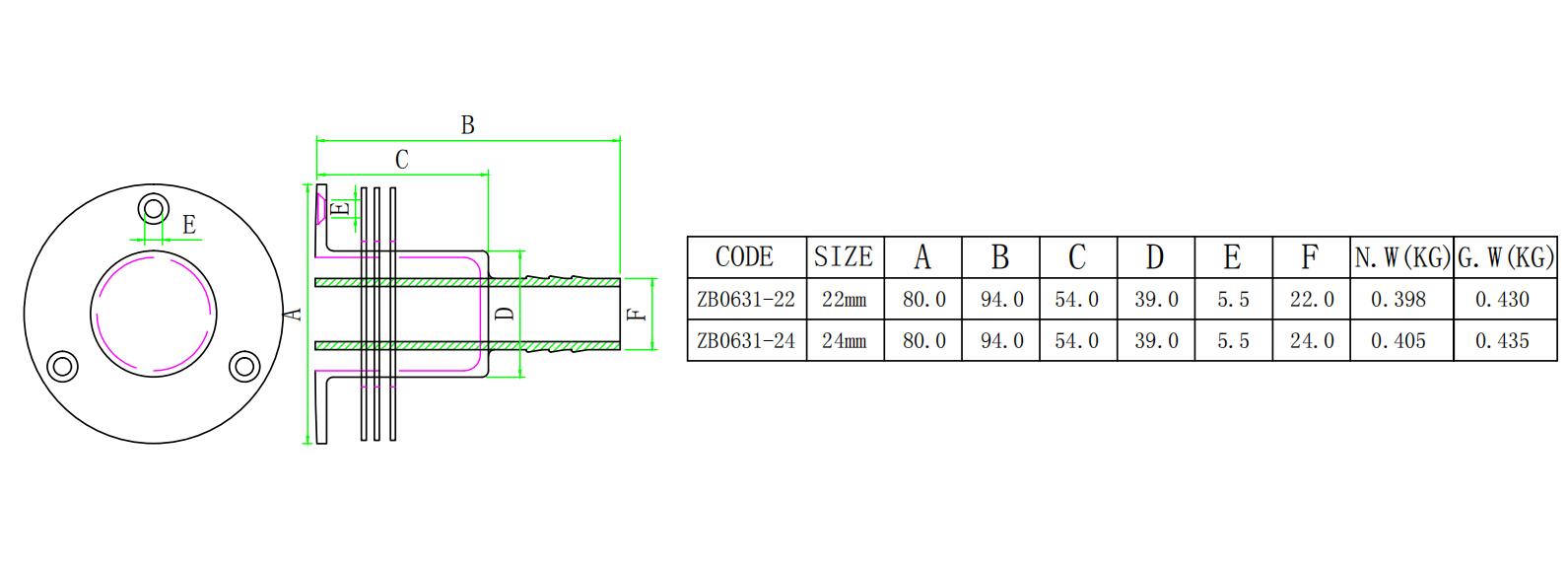

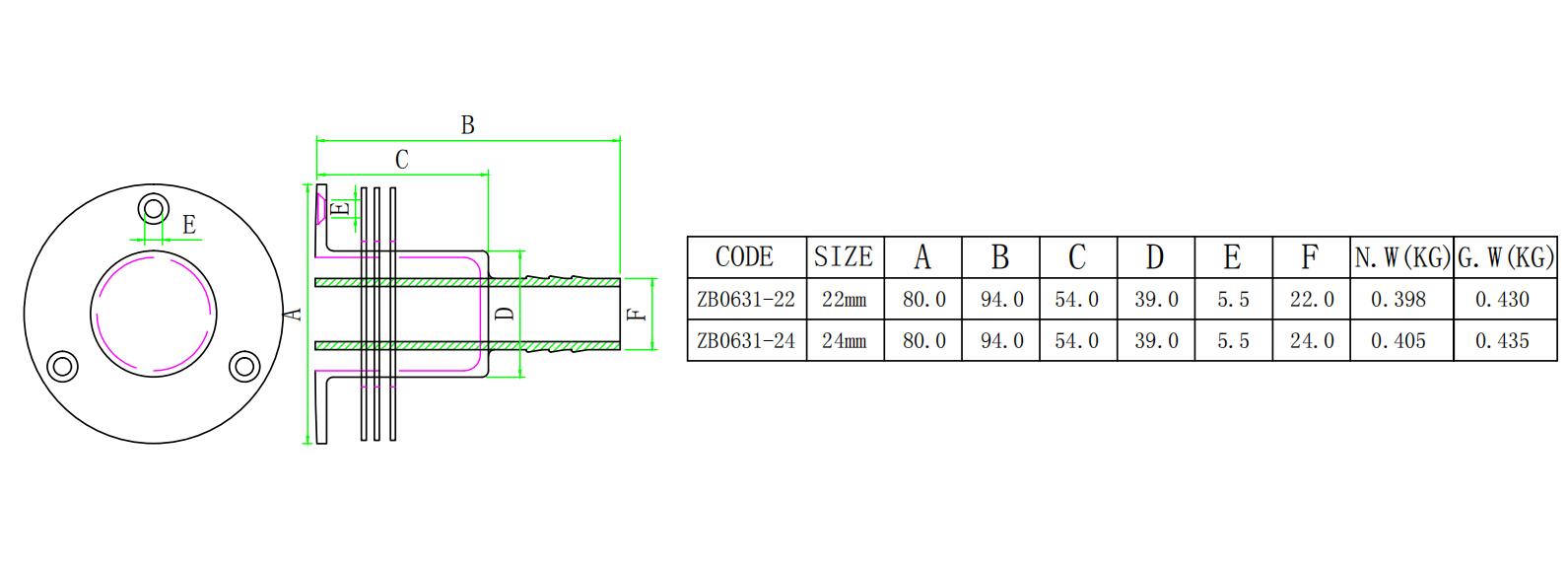

Opening Diameter:

22mm and 24mm

Product Advantage

1. Superior Corrosion Resistance

Crafted from marine-grade stainless steel, it effectively withstands saltwater, humidity and harsh maritime conditions, ensuring long-lasting performance without rusting.

2. High-Temperature Tolerance

Engineered to handle high-temperature steam discharge stably, it resists thermal deformation and maintains structural integrity under extreme heat.

3. Smooth & Unobstructed Flow

Features a polished inner wall that minimizes steam resistance, enabling fast, efficient exhaust and preventing pressure buildup in marine systems.

Specifications & Dimensions

Application Scenarios

1. Ship Engine Rooms

Discharges high-temperature steam generated by marine main engines and auxiliary power units.

2. Marine Boiler Systems

Exhausts excess steam from shipboard boilers to maintain stable pressure and operational safety.

3. Offshore Platform Power Stations

Handles steam venting for offshore power generation and heating equipment in saltwater environments.

FAQ:

1.If it's "stainless," why does it sometimes rust?

Stainless steel is stain-less, not stain-proof. Rust can occur due to:

· Contamination: Iron or carbon steel particles from tools, dock grit, or nearby grinding can settle on the stainless surface and rust. This is called "surface contamination."

· Crevice Corrosion: In tight, oxygen-deprived spaces (under a bolt head, inside a threaded fitting), the protective layer can break down, leading to corrosion.

· Galvanic Corrosion: When stainless steel is electrically connected to a less noble metal (like aluminum or mild steel) in seawater, the electrolyte (saltwater) causes a current to flow, corroding the less noble metal. The stainless can also be attacked if its potential is shifted.

· Pitting: Chlorides can locally break down the passive layer, causing small, deep pits.

· Low-Quality Alloy: Using 304 instead of 316 in a marine environment will almost certainly lead to corrosion.

2. What’s the “grain” on stainless steel?

A visible pattern from manufacturing (brushing/rolling); clean along the grain to avoid scratches.

3.Can I use bleach to clean stainless steel?

Not recommended—bleach can damage the oxide layer and cause pitting.

Packing&Delivery

Exhibition