Product Introduction

Anti-Rust & Salt-Water Ready

CNC-machined from marine-grade 316 stainless steel, molybdenum-stabilised for lifetime immunity to salt spray, brine and tropical humidity.

Heavy-Duty Backbone

One-piece 5 mm solid body—20 % thicker than DIN-standard bases—handles high cantilever & impact loads without flex or fatigue.

60° Quick-Fit Geometry

Precision-cast round foot with pre-set 60° angle eliminates on-board mitring; drop-in replacement for 7/8" (22 mm) & 1" (25 mm) rails.

Silent & Safe

Deep 90° saddle keeps rail clear of walking surfaces; no tripping, no rattling, no metal-on-metal squeal.

Versatile Mounting

Three Ø6 mm countersunk holes on 360° bolt-circle give unlimited orientation on decks, cabin tops, toe-rails, pulpits, T-tops and radar arches.

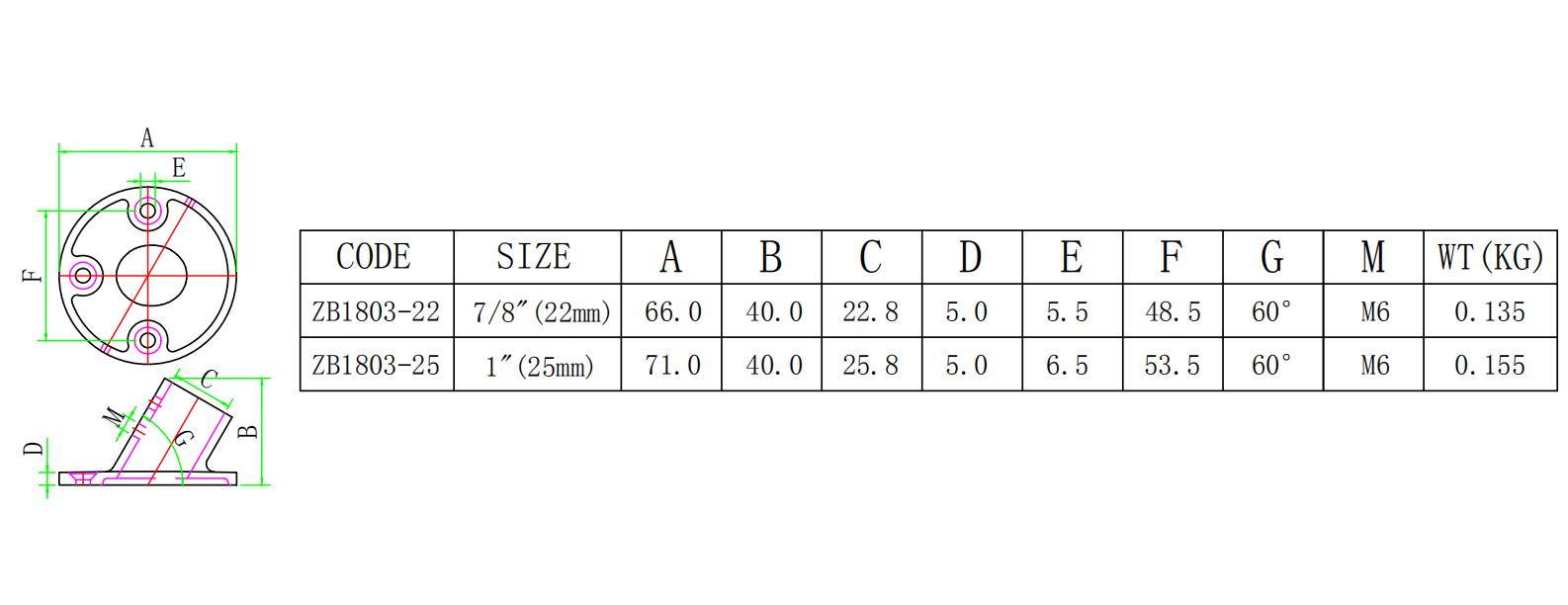

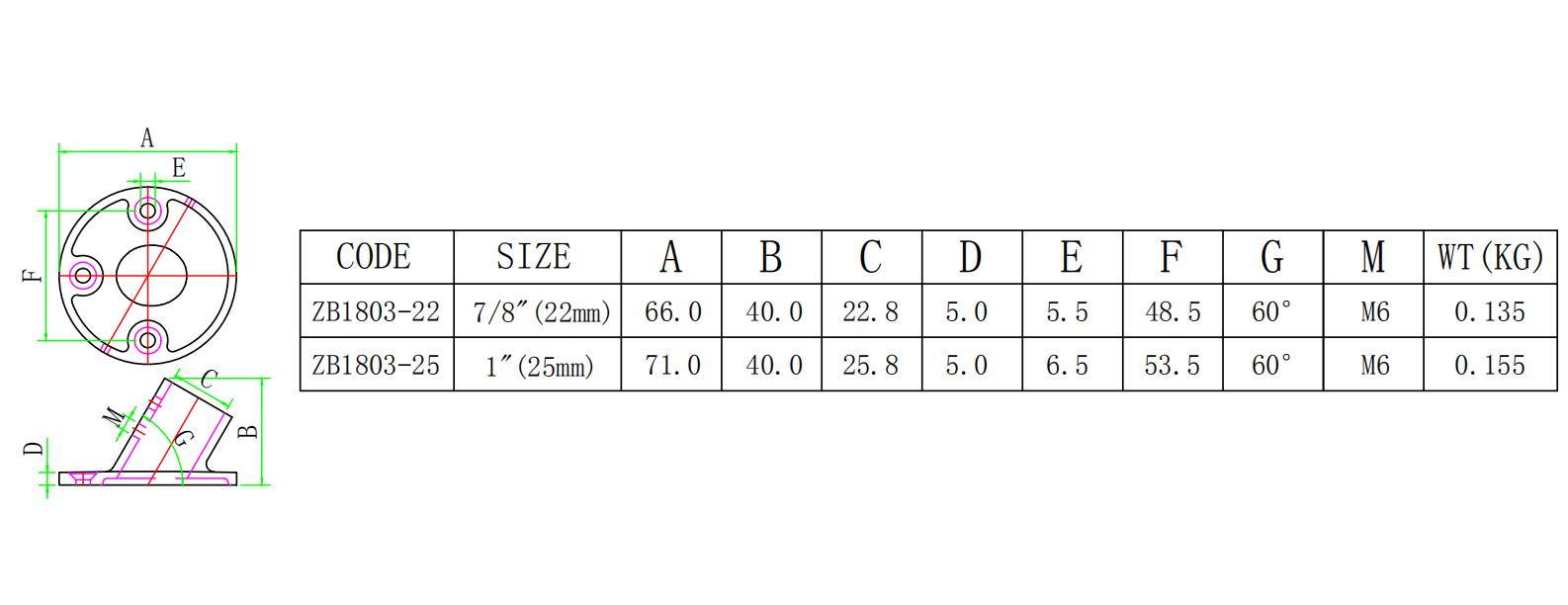

⚙️ Technical Parameters

Application Matrix

| Application | Function | Marine Value |

| Push-Pit / Pull-Pit Rails | 60° corner support for life-line terminations | Maintains rail height & tension under ISO 15085 |

| T-Top & Bimini Frames | Corner brace for overhead structures | Survives green-water impact & 100 km/h wind gusts |

| Radar Arch Supports | Diagonal strut footing | Zero corrosion staining on white gel-coat |

| Bow Rail Wing Extensions | Retrofit anchor-roller wings | Faster turnaround than full rail replacement |

| Cabin-Top Hand-Hold Rails | Corner anchor for safety rails | Sure grip even when drenched in spray |

FAQ

Q1: Can I weld this base after installation?

A: Yes—316L composition allows TIG field welding; polish heat tint with included restore pad.

Q2: Do I need isolating washers for dissimilar metals?

A: Not for 316-to-316 joints; use PTFE tape when bolting to aluminium to stop galvanic attack.

Q3: Is the quoted SWL per base or per pair?

A: Per single base; always divide rail load by number of supports.

Q4: Will the 22 mm version accept 25 mm rail with a shim?

A: We recommend ordering the correct size; wall thickness is optimised for slip-fit strength.

Q5: How do I maintain the mirror finish?

A: Rinse with fresh water after each voyage; periodic wipe with pH-neutral stainless polish keeps the yacht-club shine.

Packing & Delivery