316 Stainless Steel Marine 90° Round Rail Base

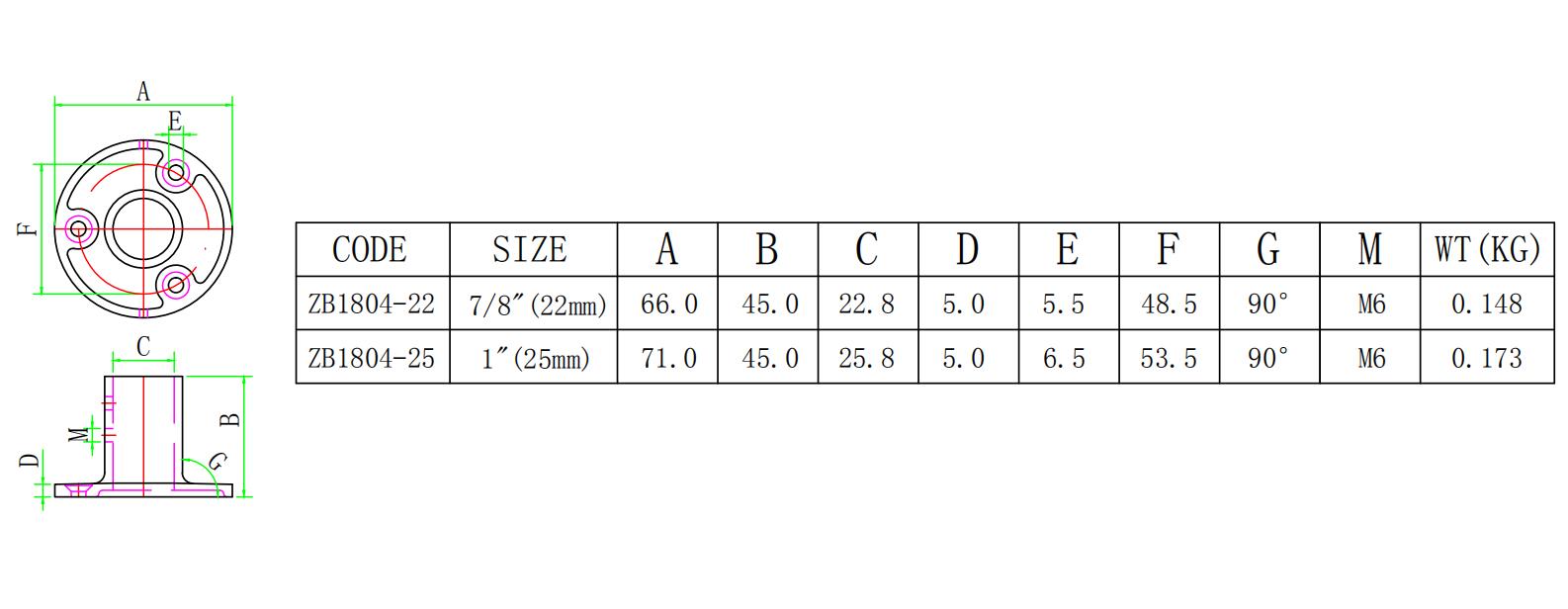

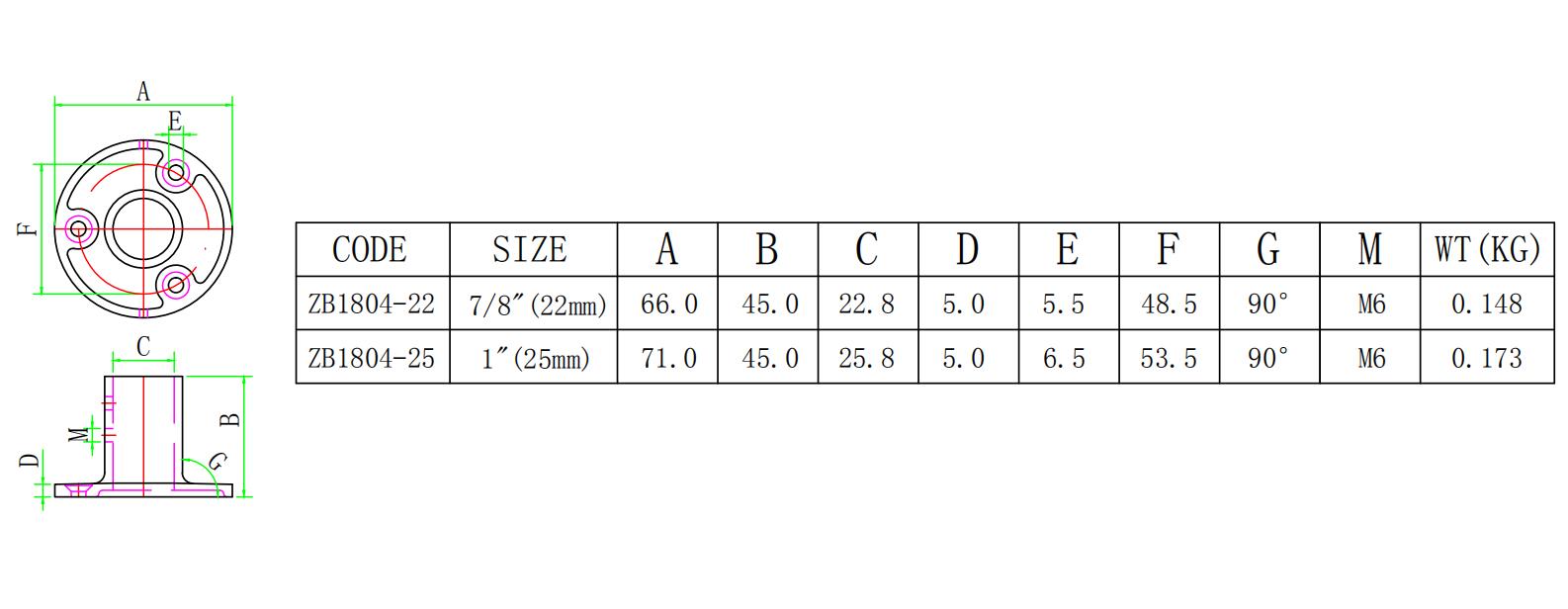

Model: ZB1804-22(7/8")/ ZB1804-25(1")

Material: Full 316 marine-grade stainless steel, precision casting + CNC finish

Function: 90° fixed-angle rail base for 22 mm & 25 mm round tubes—mirror-polished, salt-water ready, zero maintenance.

Product Highlights

| Feature | Benefit |

| Marine 316 SS | Molybdenum alloy resists pitting & crevice corrosion in open ocean. |

| One-piece Casting | No weld seams = no weak points; load capacity 30 % higher than fabricated bases. |

| 90° Precision Angle | Rail posts stay perfectly upright; eliminates leaning caused by adjustable bases. |

| Mirror Polish 400 grit Ra ≤ 0.4 µm | Yacht-grade finish; self-cleaning, fingerprints wipe off in seconds. |

| Hidden M6 Fastening | Counter-sunk holes flush with deck—no snags on lines or bare feet. |

| Weight Optimized | 22 mm model only 148 g, 25 mm model 173 g—light yet strong. |

Technical Parameters

Competitive Advantages

316 Performance at 304 Price – investment-cast in bulk, cost down 18 %.

No Weld Stain – single-piece body eliminates post-weld pickling & rust rings.

Quick Fit – 4 × M6 slots allow ±2 mm adjustment for mis-aligned studs.

Silent Grip – micro-knurled bore locks tube with no squeak or rotation.

Salt-Spray Certified >1 000 h ASTM B117 – no red rust, no pitting.

Applications

| Location | Role | Marine Value |

| Bow pulpit | Upright rail base | Withstand green-water impact |

| Stern rail | Flag-pole socket | Mirror finish matches yacht aesthetics |

| Cabin-top hand-rail | 90° corner post | Keeps walkway clear, no protruding hardware |

| Swim platform | Grab-rail foot | Immune to chronic chlorine & salt exposure |

| Fly-bridge seat rail | Pedestal mount | Vibration-proof after years of pounding |

| Davit pad-eye rail | Lifting post base | Safe Working Load aligned with davit SWL |

Installation Guide

Position base on marked deck, drill 4 × Ø6 mm pilot holes.

Bed with polyurethane sealant (3M 5200 or equivalent).

Fix with supplied A4-316 M6 × 30 mm countersunk screws.

Slide rail into base, tighten side M6 grub screw (included) to 8 N·m.

Allow sealant 24 h cure before loading.

FAQ

Q1: Can I weld this base to my rail?

A: Not recommended—cast 316 has 0.03 % max carbon; TIG welding risks carbide precipitate. Use mechanical fix plus grub screw for best corrosion result.

Q2: Will it fit 25.4 mm (1" IPS) tube?

A: ZB1804-25 bore is 25.8 mm, perfect for 25 mm ISO tube; for 25.4 mm IPS schedule 40 tube please order +0.6 mm oversize bore (custom MOQ 200 pcs).

Q3: Does the base come with backing plate?

A: Standard supply is base only; 316 backing plate 3 mm thick available as accessory (part no. ZB1804-BP).

Q4: How do I remove brown surface tea-stain?

A: Wipe with 10 % citric acid or Star brite Rust Stain Remover, rinse with fresh water, polish with microfiber—mirror finish restored.

Packing & Delivery

Exhibition

1. Why does stainless steel have magnetism?

Often, people use magnets to test the quality of stainless steel. If a magnet doesn't attract and has no magnetism, it is genuine and of good value. On the contrary, it is regarded as a counterfeit. In fact, this is an extremely one-sided and unrealistic method of wrong identification.

Austenitic stainless steel is non-magnetic or weakly magnetic. Martensitic or ferritic stainless steel is magnetic. However, when austenitic stainless steel undergoes cold working, the microstructure of the processed area will also transform into martensite. The greater the degree of processing deformation, the more martensitic transformation occurs and the greater the magnetic property. The material of the product will not change. More professional methods should be adopted to test the material of stainless steel. (Spectral detection, stainless steel identification liquid detection).

2. Why does stainless steel rust?

a. When dust containing other metal elements or particles of dissimilar metals accumulate on the surface of stainless steel, in a humid environment, the condensate water between the adherent and the stainless steel forms a micro-battery, triggering an electrochemical reaction and damaging the protective film. This is known as electrochemical corrosion.

b. When organic substances such as vegetable juice, noodle soup, and phlegm adhere to the surface of stainless steel, they form organic acids in the presence of water and oxygen. Over a long period of time, these organic acids will corrode the metal surface.

c. The stainless steel surface adheres to substances containing acids, alkalis and salts (such as splashed alkali water and lime water during wall decoration), causing local corrosion.

d. In polluted air (such as that containing large amounts of sulfides, carbon oxides, and nitrogen oxides), upon encountering condensation water, liquid spots of sulfuric acid, nitric acid, and acetic acid are formed, causing chemical corrosion.